Step 1 is finding the Greenstones of course. Past blogs have covered that subject. Step 2 is to tumble the stones and discard all the bad ones.

Overwhelmed with Greenstones

I’ve been trying to catch up on my Isle Royale Greenstone cutting. Isle Royale Greenstone (Chlorastrolite) is the Official State Gemstone of Michigan). This can get overwhelming. Unless you work with Greenstones, you have no idea what is involved, so let me walk you through the steps.

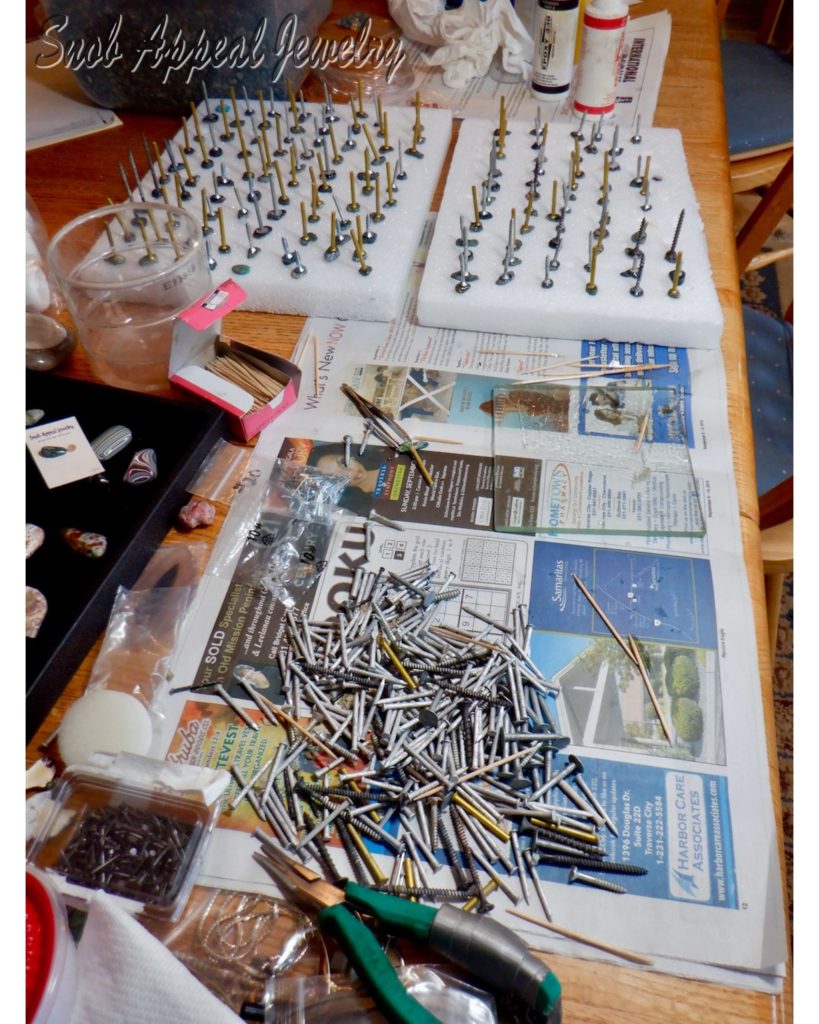

I never do fewer then 100 Greenstones. I flatten the backs and glue then to nailheads, screws, rivets, or whatever I have.

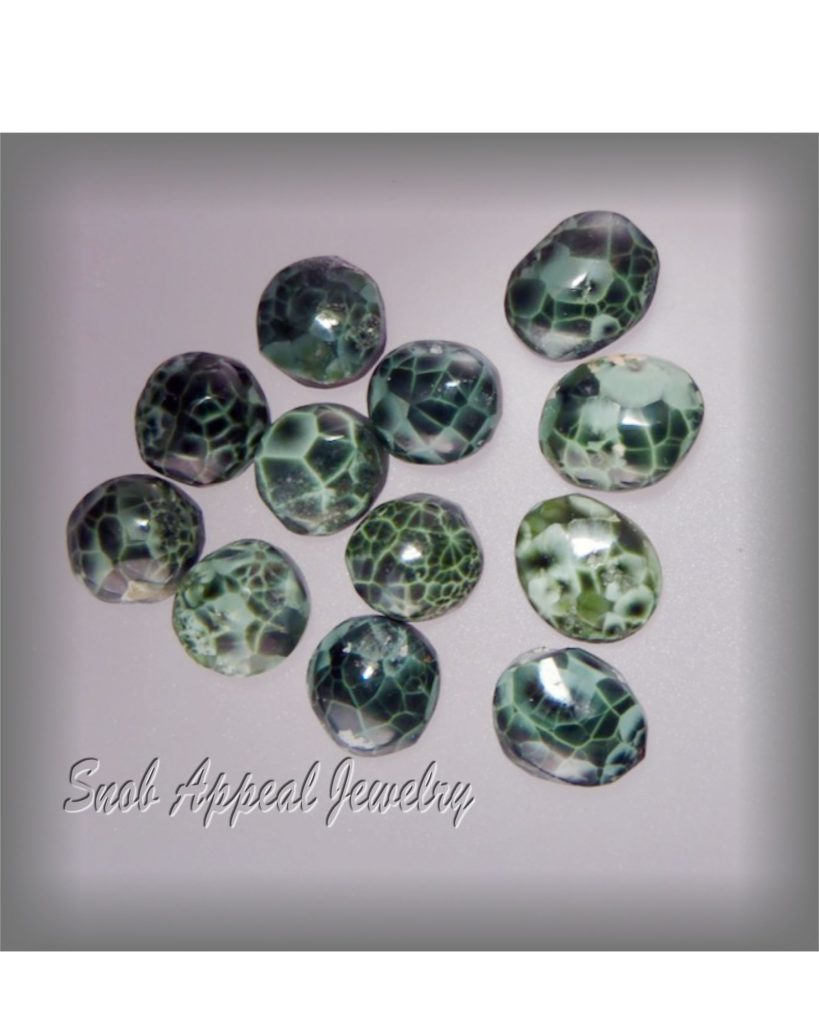

These Greenstones are awaiting the final three soft wheels, before final polish.

BIG BATCHES

I don’t cut Michigan Greenstones unless I am doing a big batch. Right now I’m working on 200, so I can produce a hundred new earring pairs. In order to find 200 good Greenstones involves going through at least 600 stones.

Add these earrings to my goal of 100 pendants, to be made over the winter, and you can see why I’m swamped.

There are Greenstones everywhere in various stages; on the table, in the shop, and in the kitchen. Fortunately Bonnie is patient and doesn’t carp much. We have not seen the top of the dining room table in a month, but it’s a necessary evil to getting these Greenstones fit for jewelry, or to sell to others for jewelry making.

Prepping Procedure

The procedure for prepping Greenstones involves tumbling the stones to take the Chlorite rind off. Tumbling destroys the weak stones, and brings out the pattern on the good ones. When they come out of the tumbler, I sort out the Greenstones with promise, and pitch the bad ones. The minimal grade Greenstones go into Grab Bags that we sell at our shows. The tumbling usually weeds out 2/3 of the stones.

Next I take the remaining stones and flatten the backs (the worst sides) to prepare for dopping. Most of these are small stones about half the size of a pea.

I glue the Greenstones to rivets or nail heads. Epoxy is faster for me, but you could use dop wax. The dopped stones are left overnight to dry. The stones are then taken to my shop and worked up on my Genie or Titan. This process can take some time to bring out the best in each stone. The stones go through all the soft wheels (Never use the hard wheels on GS). The hard wheels most often produce harmonic vibrations that can cause the stones to blow apart.

A before and after shot. You never know how fine a Greenstone is, until it’s finished. The bottom stone needs a little more work to remove some remaining flaws.

I Discard Many Substandard Stones

During this machine procedure I invariably discover some hollow stones. Other stones are not great or substandard. Again more are discarded.

Here’s a before and after shot of the same Greenstone. The second stone needs a little more work to get out remaining flaws.

At this point I must point out that Isle Royale Greenstones are one of the trickiest gemstones to cut. You must know exactly when to stop grinding at every stage. Some have very thin pattern layers, while others are good throughout the stone. You have to almost see, in your mind, if what you do will enhance the stone you are working on, or ruin it. You can only gain these answers through experience cutting loads of greenstones. I have cut many thousands in my day, so I have a “feel” for these beauties. There is never any answer that is always correct. Sadly, I admit to ruining many thousands of dollars worth of stones.

Taking my time is worth the effort

Taking the time to get it right, is the way I roll. These are calibrated ring stones for a jeweler customer.

Sometimes I am cutting a very fine Greenstone, that may be worth $500 or more, and that stone breaks through into a hollow area. I have sometimes cut right thru the pattern layer, thinking the pattern would get better. Stones have flown out of my hands and get broken or lost in the workshop Nexus. Recently Bonnie found one I remember losing long ago. She claims that is an advantage to cleaning up. I have learned from every mistake, and after making the same mistake several times, I often believe I have learned my lesson. Cutting Greenstones is not cheap. “OOPS, there went another hundred bucks”..

Bonnie’s New Pendant…NOT!

I had this sitting on the table. I told Bonnie it was laid out for a new pendant for her. NOT!

The stones get soaked in a solvent to get them off the dops after they are polished. This takes several hours, then I go through a quality control with the entire batch, and weed again (Do you see a pattern here?). Greenstones are an amazing amount of trouble and work, and being that they are generally small, makes it harder, not easier. No one should ever complaint about the price of a Greenstone. A really good one is so rare.

I am going to start making Greenstone beads in the near future; I’ll admit this is a bit over the top, but I just have to try it.

A pair of perfect Greenstone Cabochons.

Custom Greenstone Cutting

If you have a Greenstone that you want me to work on for you, there is a procedure. First I need clean pictures with something (like a dime) in the picture (preferably several pictures). Many people that have what they think is a Greenstone, have something else. Next, if we agree there is a good possibility of success, you send the stone for evaluation. This allows me to see if your stone is viable for cutting and polishing. Thirdly, I honestly tell you what I think.

If you OK with everything, I cut and polish ,with no guarantee of success. My odds of producing a good gem are around 90%. If you provide a good stone, you’ll get a good result. I can never assure anyone that there are no internal flaws, cracks, or voids in the stone. I wish I had Xray vision, but I do not. I address any customer stone as if it were my own.

Once we reach the cutting and polishing stage, my odds are around 90%. If the stone is flawed, you would not have wanted it anyway. Thus far, I have been close to perfect on customer’s custom cutting.

I know this blog has not been my norm, but I think being buried in Greenstones has somewhat effected my head. I’ve wanted to explain what it takes to get you a good piece of Greenstone Jewelry, so now you know some of it. Visit our Greenstone Cabochon pages for cut stones you can use in your own jewelry, or see our Greenstone Pendant pages and Greenstone Earring page for currently available jewelry. Oh; we have Tie Tacks also! Does anyone still wear them? (Or they can be ordered as pins.) Enjoy Michigan’s State Gem, a rare and special stone found nowhere else on earth.

Read more about Greenstones or about The Shades and Patterns of Greenstone or a Greenstone Hunt in the Rain.